Stroj na elektroiskrové hĺbenieGF Machining Solutions

FORM 300

Stroj na elektroiskrové hĺbenie

GF Machining Solutions

FORM 300

Rok výroby

2015

Stav

Použitý

Umiestnenie

Nürtingen

Zobraziť obrázky

Zobraziť mapu

Údaje o stroji

- Popis stroja:

- Stroj na elektroiskrové hĺbenie

- Výrobca:

- GF Machining Solutions

- Model:

- FORM 300

- Rok výroby:

- 2015

- Stav:

- generálne opravený (použitý)

- Funkčnosť:

- plne funkčný

Cena a lokalita

- Umiestnenie:

- Großer Forst 7, 72622 Nürtingen, Deutschland

Volať

Technické detaily

- Pojazdová vzdialenosť osi X:

- 600 mm

- Zdvih osi Y:

- 400 mm

- Zdvih osi Z:

- 450 mm

- Hmotnosť obrobku (max.):

- 1 600 kg

- Celková výška:

- 2 780 mm

- Celková šírka:

- 2 265 mm

- Celková dĺžka:

- 2 110 mm

- Ťah perom:

- 450 mm

- Dĺžka obrobku (max.):

- 1 220 mm

- Šírka obrobku (max.):

- 870 mm

- Výška obrobku (max.):

- 470 mm

Podrobnosti ponuky

- ID záznamu:

- A19662321

- Naposledy aktualizované:

- dňa 03.11.2025

Popis

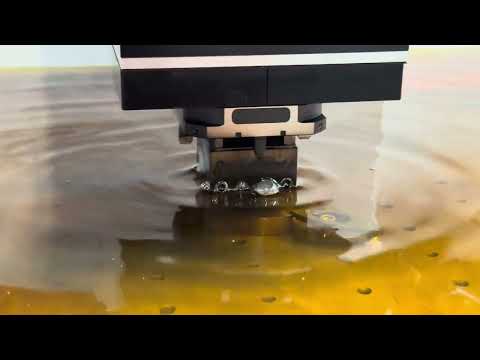

GF AgieCharmilles FORM 300, year of manufacture 2015

The GF AgieCharmilles FORM 300, built in 2015, is a powerful and precise used die-sinking EDM machine designed for demanding applications in tool and mould making. Thanks to its advanced control system, excellent surface quality, and high efficiency, it offers an outstanding investment opportunity for companies that value precision and cost-effectiveness.

Key Features & Benefits:

✅ Large working area & high load capacity:

Travels (X/Y/Z): 600 x 400 x 450 mm

Maximum workpiece size: 1220 x 870 x 470 mm

Maximum workpiece weight: 1,600 kg

Maximum electrode weight: 50 kg

✅ High-precision machining with state-of-the-art technology:

Positioning accuracy via linear glass scales (no recalibration required)

Innovative ISPG generator (Intelligent Speed Power Generator) for maximum efficiency

Adaptive control (ACC & ACO) for optimized spark discharge and reduced electrode wear

Nedpew Ebtvjfx Afkewb

Surface quality up to Ra 0.08 μm

✅ Powerful control system & automation:

AC FORM HMI with intuitive user interface & touchscreen

Automatic CAD/CAM integration for seamless data transfer

Job management with prioritization and real-time monitoring

Remote monitoring via SMS notification

✅ Maximum productivity & flexibility:

Automatic 48-position electrode changer for unattended operation

Intelligent workpiece measurement & 3D compensation

Reduced electrode wear thanks to iQ technology

✅ Reliability & low operating costs:

Robust C-frame design for high stability

Efficient dielectric management with 6 filter cartridges

Energy-efficient operation with low maintenance requirements

Ideal for:

✔ High-precision mould and tool machining

✔ Series production with the highest quality standards

✔ Complex geometries and fine surface textures

Experience maximum productivity with the GF AgieCharmilles FORM 300 – your solution for precise and cost-effective die-sinking EDM!

📌 Our used machine from 2015 is cleaned, overhauled and thoroughly tested prior to sale to ensure the highest level of quality and reliability.

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

The GF AgieCharmilles FORM 300, built in 2015, is a powerful and precise used die-sinking EDM machine designed for demanding applications in tool and mould making. Thanks to its advanced control system, excellent surface quality, and high efficiency, it offers an outstanding investment opportunity for companies that value precision and cost-effectiveness.

Key Features & Benefits:

✅ Large working area & high load capacity:

Travels (X/Y/Z): 600 x 400 x 450 mm

Maximum workpiece size: 1220 x 870 x 470 mm

Maximum workpiece weight: 1,600 kg

Maximum electrode weight: 50 kg

✅ High-precision machining with state-of-the-art technology:

Positioning accuracy via linear glass scales (no recalibration required)

Innovative ISPG generator (Intelligent Speed Power Generator) for maximum efficiency

Adaptive control (ACC & ACO) for optimized spark discharge and reduced electrode wear

Nedpew Ebtvjfx Afkewb

Surface quality up to Ra 0.08 μm

✅ Powerful control system & automation:

AC FORM HMI with intuitive user interface & touchscreen

Automatic CAD/CAM integration for seamless data transfer

Job management with prioritization and real-time monitoring

Remote monitoring via SMS notification

✅ Maximum productivity & flexibility:

Automatic 48-position electrode changer for unattended operation

Intelligent workpiece measurement & 3D compensation

Reduced electrode wear thanks to iQ technology

✅ Reliability & low operating costs:

Robust C-frame design for high stability

Efficient dielectric management with 6 filter cartridges

Energy-efficient operation with low maintenance requirements

Ideal for:

✔ High-precision mould and tool machining

✔ Series production with the highest quality standards

✔ Complex geometries and fine surface textures

Experience maximum productivity with the GF AgieCharmilles FORM 300 – your solution for precise and cost-effective die-sinking EDM!

📌 Our used machine from 2015 is cleaned, overhauled and thoroughly tested prior to sale to ensure the highest level of quality and reliability.

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

Dokumenty

Poskytovateľ

Poznámka: Zaregistrujte sa zadarmo alebo sa prihláste, aby ste získali všetky informácie.

Odoslať žiadosť

Telefón & Fax

+49 7022 ... inzercie

Tieto inzeráty by vás mohli tiež zaujímať.

Malý inzerát

Nürtingen

Nürtingen

763 km

Hĺbková elektroerozívna obrábačka (EDM)

GF Machining SolutionsFORM 300

GF Machining SolutionsFORM 300

Malý inzerát

Schömberg

Schömberg

809 km

Obrábacie centrum

HERMLEC30 U

HERMLEC30 U

Malý inzerát

Babberich

Babberich

1 027 km

Povrchová brúska 650 x 525 x 350 mm

Geibel & HotzFS 635-Z SA

Geibel & HotzFS 635-Z SA

Malý inzerát

Burgos

Burgos

1 947 km

Portálová frézka

CorreaEuro 2000

CorreaEuro 2000

Malý inzerát

Westerkappeln

Westerkappeln

927 km

Frézka na lôžko

CNC Bettfräsmaschine Universal ZAYER20 KF 4000

CNC Bettfräsmaschine Universal ZAYER20 KF 4000

Malý inzerát

Nürtingen

Nürtingen

763 km

Stroj na erodovanie drôtu

GF AgieCharmillesProgress V3

GF AgieCharmillesProgress V3

Malý inzerát

Logrezana

Logrezana

2 040 km

Obrábacie centrum

KENTVK 1600MC-2

KENTVK 1600MC-2

Malý inzerát

Dornhan

Dornhan

825 km

EDM 312MF30

ExeronSLM

ExeronSLM

Malý inzerát

Gelsenkirchen

Gelsenkirchen

954 km

Hydraulický lis

HidrobrasilDoppelständerpresse 400 Tonnen

HidrobrasilDoppelständerpresse 400 Tonnen

Malý inzerát

Thurmaston

Thurmaston

1 527 km

Vertikálne obrábacie centrum so 4. osou

DoosanDNM 6700

DoosanDNM 6700

Váš inzerát bol úspešne odstránený

Došlo k chybe