Lis na betónHidralmac

150 Tonnen Betonpresse

Lis na betón

Hidralmac

150 Tonnen Betonpresse

Rok výroby

2017

Stav

Nový

Umiestnenie

Ennepetal

Zobraziť obrázky

Zobraziť mapu

Údaje o stroji

- Popis stroja:

- Lis na betón

- Výrobca:

- Hidralmac

- Model:

- 150 Tonnen Betonpresse

- Sériové číslo:

- DF0149

- Rok výroby:

- 2017

- Stav:

- nový

Cena a lokalita

- Umiestnenie:

- Scharpenberger Str. 96-98, 58256 Ennepetal, Deutschland

Volať

Podrobnosti ponuky

- ID záznamu:

- A3871212

- Referenčné č.:

- 1358-NEBR-1215

- Naposledy aktualizované:

- dňa 27.03.2025

Popis

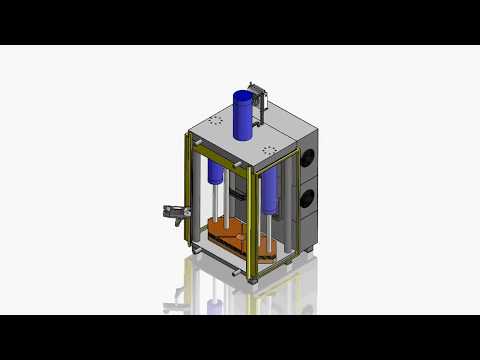

Pressure: 2x 75 / 150 t

Clearance width: 2050 x 965 mm

Stroke: 800 mm

Total power requirement: Main motor 22 kW

Machine weight approx.: 6.5 t

Required space approx.: 1500 x 1025 mm

Lower ram: 150 mm

Upper ram: 150 mm

Base plate (steel): 72 mm

Additional motors and consumers: 2 kW

Upper ram size approx.: 870 x 350 x 150 mm

Lower ram size approx.: 1500 x 600 x 150 mm

Base plate: 1500 x 1025 x 75 mm

Top plate: 1500 x 1025 x 150 mm

Guide column diameter: 120 mm

Piston rod diameter: 80 mm

Oil tank: 350 l

Oil requirement: 320 l

Travel of each of both lifting cylinders and pressure cylinder: 350 mm

Max. open height: 1600 mm

Press speed: 15 – 0 mm/sec

Lifting speed: 100 mm/sec

Window size approx.: 2050 x 965 mm

Wall thickness approx.: 6 mm

Position control accuracy via contactless sensors: 0.5 mm

The press features two column guides, each with a 120 mm diameter, which guide both the lower and the upper ram. The guides are made of bronze.

The lower ram is designed to be extremely robust with a thickness of 150 mm.

The upper ram also features a 150 mm thick steel plate.

The machine’s base plate is fabricated from 72 mm thick steel to ensure stability during movement; therefore, the oil tank with the hydraulic unit is also positioned close to the floor.

Both the hydraulics and the electronics are permanently attached to the machine and are protected from contamination by an integrated cabinet.

To dissipate the resulting heat, the machine is equipped with an oil cooler mounted on top of the press. The control cabinet is also fitted with air cooling.

Bedpod Aftpefx Af Sowi

For any future maintenance work on the hydraulics, the rear interior wall of the press can be easily removed.

The two-hand control is permanently mounted to facilitate transport but is jointed and movable.

High-resolution safety light curtains prevent personnel from entering the hazardous area.

To ensure convenient operation, the machine is equipped on both sides with transparent acrylic windows (6 mm thick) that may require replacement with new panels after years of use, but at minimal cost.

In addition, the press is fitted with 4 powerful LED lights integrated into the top plate.

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

Clearance width: 2050 x 965 mm

Stroke: 800 mm

Total power requirement: Main motor 22 kW

Machine weight approx.: 6.5 t

Required space approx.: 1500 x 1025 mm

Lower ram: 150 mm

Upper ram: 150 mm

Base plate (steel): 72 mm

Additional motors and consumers: 2 kW

Upper ram size approx.: 870 x 350 x 150 mm

Lower ram size approx.: 1500 x 600 x 150 mm

Base plate: 1500 x 1025 x 75 mm

Top plate: 1500 x 1025 x 150 mm

Guide column diameter: 120 mm

Piston rod diameter: 80 mm

Oil tank: 350 l

Oil requirement: 320 l

Travel of each of both lifting cylinders and pressure cylinder: 350 mm

Max. open height: 1600 mm

Press speed: 15 – 0 mm/sec

Lifting speed: 100 mm/sec

Window size approx.: 2050 x 965 mm

Wall thickness approx.: 6 mm

Position control accuracy via contactless sensors: 0.5 mm

The press features two column guides, each with a 120 mm diameter, which guide both the lower and the upper ram. The guides are made of bronze.

The lower ram is designed to be extremely robust with a thickness of 150 mm.

The upper ram also features a 150 mm thick steel plate.

The machine’s base plate is fabricated from 72 mm thick steel to ensure stability during movement; therefore, the oil tank with the hydraulic unit is also positioned close to the floor.

Both the hydraulics and the electronics are permanently attached to the machine and are protected from contamination by an integrated cabinet.

To dissipate the resulting heat, the machine is equipped with an oil cooler mounted on top of the press. The control cabinet is also fitted with air cooling.

Bedpod Aftpefx Af Sowi

For any future maintenance work on the hydraulics, the rear interior wall of the press can be easily removed.

The two-hand control is permanently mounted to facilitate transport but is jointed and movable.

High-resolution safety light curtains prevent personnel from entering the hazardous area.

To ensure convenient operation, the machine is equipped on both sides with transparent acrylic windows (6 mm thick) that may require replacement with new panels after years of use, but at minimal cost.

In addition, the press is fitted with 4 powerful LED lights integrated into the top plate.

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

Poskytovateľ

Poznámka: Zaregistrujte sa zadarmo alebo sa prihláste, aby ste získali všetky informácie.

Odoslať žiadosť

Telefón & Fax

+49 209 9... inzercie

Tieto inzeráty by vás mohli tiež zaujímať.

Malý inzerát

Taliansko

Taliansko

940 km

Kompletne zrekonštruované horúce radiálne kovanie

CNC GFMSX-13

CNC GFMSX-13

Malý inzerát

Oftersheim

Oftersheim

815 km

Hydraulická jednotka

Parker

Parker

Malý inzerát

Nemecko

Nemecko

604 km

Brúska na valce - univerzálna

KIKINDAD15 - 2600/250

KIKINDAD15 - 2600/250

Malý inzerát

Nemecko

Nemecko

718 km

CNC sústružnícke a frézovacie centrum

Niles-SimmonsN30/2500 MC

Niles-SimmonsN30/2500 MC

Malý inzerát

Hochdorf

Hochdorf

751 km

Chladiaca jednotka teploty (TCU) / Chladič

SingleChill Plus Testing CHT-130

SingleChill Plus Testing CHT-130

Malý inzerát

Ciriè

Ciriè

994 km

Dvojstĺpový hydraulický lis

EMANUELDEA 400/2000

EMANUELDEA 400/2000

Malý inzerát

Fuldatal

Fuldatal

786 km

Cyklus riadený sústruh

Weisser HeinbronnHECKTOR CNC 295x2000

Weisser HeinbronnHECKTOR CNC 295x2000

Malý inzerát

Neumarkt in der Oberpfalz

Neumarkt in der Oberpfalz

606 km

Dvojpalivový horák Weishaupt GL7-1750kW

Weishaupt GL7-1750kW Zweistoffbrenner1D-ZMD

Weishaupt GL7-1750kW Zweistoffbrenner1D-ZMD

Malý inzerát

Mozé-sur-Louet

Mozé-sur-Louet

1 511 km

Lisovacia brzda

PromecamPPH25.12B

PromecamPPH25.12B

Malý inzerát

Dellach

Dellach

545 km

Nástroj brúske

Hispano SuizaAlbula

Hispano SuizaAlbula

Váš inzerát bol úspešne odstránený

Došlo k chybe