AKO 100 (PRENÁJOM ZARIADENÍ)Hosokawa Alpine

AS Aeroplex

AKO 100 (PRENÁJOM ZARIADENÍ)

Hosokawa Alpine

AS Aeroplex

Rok výroby

2023

Stav

Nový

Umiestnenie

Augsburg

Zobraziť obrázky

Zobraziť mapu

Údaje o stroji

- Popis stroja:

- AKO 100 (PRENÁJOM ZARIADENÍ)

- Výrobca:

- Hosokawa Alpine

- Model:

- AS Aeroplex

- Rok výroby:

- 2023

- Stav:

- nový

- funkčnosť:

- plne funkčný

Cena a lokalita

- Umiestnenie:

- Peter-Dörfler-Straße 13-25, 86199 Augsburg, DE

- prenájom:

- je možné

Volať

Podrobnosti ponuky

- ID záznamu:

- A14383945

- Naposledy aktualizované:

- dňa 10.02.2025

Popis

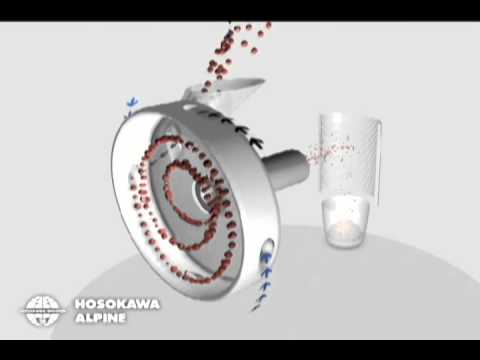

Hosokawa Alpine AS 100 Aeroplex Rental System

The Hosokawa Alpine Aeroplex AS spiral jet mill is a simple jet micronizer without a dynamic classifier (unlike the Hosokawa Alpine AFG), enabling ultra-fine micronization and achieving a product fineness of between 10 and 150µm across various materials. It is primarily used for processing dry, non-abrasive materials with hardness up to 3 Mohs, although certain models can be equipped with wear-resistant liners. The classifier-free design of this granulator—featuring no moving parts (thus no bearings or lubrication)—makes it ideal for pharmaceutical or food applications, and it is also suitable for use in the chemical industry, for example.

Grinding occurs within the milling chamber, where the product is accelerated by compressed gas injected through the grinding nozzles, causing the particles to collide, fracture, and thereby reduce their size. Once sufficiently fine, particles are drawn to the central outlet of the mill, which acts as a static classifier, although the maximum particle cut is not as sharp compared to the AFG (which uses a classifier wheel). The next process step typically involves discharge from the system via cyclone or air filter. Due to the significant volume of air required, the temperature increase is much lower than with other milling or pulverizing technologies. Adjustment of the final particle size distribution is easily achieved by changing parameters such as the gas pressure at the grinding nozzles, product injector settings, air volume, feed rate, and more.

A HOSOKAWA ALPINE Originals machine:

• Refurbished by the original manufacturer

• Exclusive use of original components

• Backed by the original manufacturer’s warranty

• Guaranteed spare parts supply directly from the manufacturer

• Reduced delivery times

• Prior to delivery, the machine is inspected, all wear parts checked and replaced if necessary, and the machine is customized to your specific requirements

• Option to supply all required peripherals or integrate into your existing production plant

• We are also interested in purchasing used HOSOKAWA ALPINE equipment

Technical details:

Gedpfx Agoq A T Ilsuekc

• Stainless steel, pharmaceutical-grade construction

• No explosion protection (NPSR); can be operated under inert gas (N2)

• Batch operation, typically handling quantities as small as a few grams (depending on material)

Scope of supply:

• Complete small-scale system, including dosing channel, AS spiral jet mill, manual controls, and filter

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

The Hosokawa Alpine Aeroplex AS spiral jet mill is a simple jet micronizer without a dynamic classifier (unlike the Hosokawa Alpine AFG), enabling ultra-fine micronization and achieving a product fineness of between 10 and 150µm across various materials. It is primarily used for processing dry, non-abrasive materials with hardness up to 3 Mohs, although certain models can be equipped with wear-resistant liners. The classifier-free design of this granulator—featuring no moving parts (thus no bearings or lubrication)—makes it ideal for pharmaceutical or food applications, and it is also suitable for use in the chemical industry, for example.

Grinding occurs within the milling chamber, where the product is accelerated by compressed gas injected through the grinding nozzles, causing the particles to collide, fracture, and thereby reduce their size. Once sufficiently fine, particles are drawn to the central outlet of the mill, which acts as a static classifier, although the maximum particle cut is not as sharp compared to the AFG (which uses a classifier wheel). The next process step typically involves discharge from the system via cyclone or air filter. Due to the significant volume of air required, the temperature increase is much lower than with other milling or pulverizing technologies. Adjustment of the final particle size distribution is easily achieved by changing parameters such as the gas pressure at the grinding nozzles, product injector settings, air volume, feed rate, and more.

A HOSOKAWA ALPINE Originals machine:

• Refurbished by the original manufacturer

• Exclusive use of original components

• Backed by the original manufacturer’s warranty

• Guaranteed spare parts supply directly from the manufacturer

• Reduced delivery times

• Prior to delivery, the machine is inspected, all wear parts checked and replaced if necessary, and the machine is customized to your specific requirements

• Option to supply all required peripherals or integrate into your existing production plant

• We are also interested in purchasing used HOSOKAWA ALPINE equipment

Technical details:

Gedpfx Agoq A T Ilsuekc

• Stainless steel, pharmaceutical-grade construction

• No explosion protection (NPSR); can be operated under inert gas (N2)

• Batch operation, typically handling quantities as small as a few grams (depending on material)

Scope of supply:

• Complete small-scale system, including dosing channel, AS spiral jet mill, manual controls, and filter

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

Poskytovateľ

Poznámka: Zaregistrujte sa zadarmo alebo sa prihláste, aby ste získali všetky informácie.

Registrované od: 2019

Odoslať žiadosť

Telefón & Fax

+49 821 2... inzercie

Váš inzerát bol úspešne odstránený

Došlo k chybe