Vysokorýchlostný granulátorZERMA

GST 250/600

Vysokorýchlostný granulátor

ZERMA

GST 250/600

Počiatočná cena bez DPH

19 400 €

Rok výroby

2025

Stav

Nový

Umiestnenie

Buchholz in der Nordheide

Zobraziť obrázky

Zobraziť mapu

Údaje o stroji

Cena a lokalita

Počiatočná cena bez DPH

19 400 €

- Umiestnenie:

- Vaenser Weg 12, 21244 Buchholz in der Nordheide, Deutschland

Volať

Podrobnosti ponuky

- ID záznamu:

- A13548352

- Naposledy aktualizované:

- dňa 03.05.2025

Popis

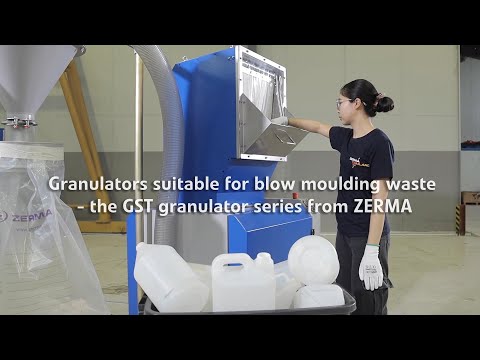

Shredding of large-volume blow-molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with particular emphasis on weight, handling, and energy efficiency. These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The cutters are available with a 250 mm rotor diameter and widths of 300, 450, or 600 mm. The curved rear wall of the cutting chamber ensures aggressive material infeed and prevents material blockage. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine, thus reducing downtime during maintenance.

The strongly tangential, curved rear wall of the cutting chamber, in combination with the aggressive open rotor design, ensures reliable material intake and minimizes the risk of blockages. These compact granulators are suitable for use in blow-molding operations. They are ideal for recycling applications involving bulky items such as bottles, canisters, and crates. Thanks to the low feed height, the machines can be conveniently loaded by hand or with a small conveyor belt. The low noise emission and compact footprint make this granulator the perfect solution for inline granulation.

Optional rear wall with raised stator knife (M version):

The feed method with a raised stator knife is better suited for thicker-walled and more compact parts, such as injection-molded items, profiles, sheets, etc. Due to the cutting geometry and the reduced aggressiveness of the rotor, a high-quality regrind is produced regardless of material type or shape, such as injection-molded parts, profiles, sheets, and so on.

Control system and control cabinet:

The integrated control and operator console not only meets all current safety regulations, but can also be tailored to specific requirements. In addition, peripheral devices such as feeding conveyors, metal detection, and discharge systems can be seamlessly integrated into the machine’s control system. For improved efficiency, an optional intelligent energy-saving function is available, which reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream equipment.

Standard configuration with blower, 0.75 kW power consumption, and 400 mm cyclone

Rotor diameter (mm): 250

Nodpjp Sr Iaofx Af Rskt

Rotor width (mm): 600

Drive (kW): 11

Number of rotor knives: 3 x 2

Number of stator knives: 2

Screen perforation (mm): > 6

Approx. weight (kg): 1450

Feed opening (mm): 380 x 600

Feed opening option for M version (mm): 295 x 600

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with particular emphasis on weight, handling, and energy efficiency. These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The cutters are available with a 250 mm rotor diameter and widths of 300, 450, or 600 mm. The curved rear wall of the cutting chamber ensures aggressive material infeed and prevents material blockage. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine, thus reducing downtime during maintenance.

The strongly tangential, curved rear wall of the cutting chamber, in combination with the aggressive open rotor design, ensures reliable material intake and minimizes the risk of blockages. These compact granulators are suitable for use in blow-molding operations. They are ideal for recycling applications involving bulky items such as bottles, canisters, and crates. Thanks to the low feed height, the machines can be conveniently loaded by hand or with a small conveyor belt. The low noise emission and compact footprint make this granulator the perfect solution for inline granulation.

Optional rear wall with raised stator knife (M version):

The feed method with a raised stator knife is better suited for thicker-walled and more compact parts, such as injection-molded items, profiles, sheets, etc. Due to the cutting geometry and the reduced aggressiveness of the rotor, a high-quality regrind is produced regardless of material type or shape, such as injection-molded parts, profiles, sheets, and so on.

Control system and control cabinet:

The integrated control and operator console not only meets all current safety regulations, but can also be tailored to specific requirements. In addition, peripheral devices such as feeding conveyors, metal detection, and discharge systems can be seamlessly integrated into the machine’s control system. For improved efficiency, an optional intelligent energy-saving function is available, which reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream equipment.

Standard configuration with blower, 0.75 kW power consumption, and 400 mm cyclone

Rotor diameter (mm): 250

Nodpjp Sr Iaofx Af Rskt

Rotor width (mm): 600

Drive (kW): 11

Number of rotor knives: 3 x 2

Number of stator knives: 2

Screen perforation (mm): > 6

Approx. weight (kg): 1450

Feed opening (mm): 380 x 600

Feed opening option for M version (mm): 295 x 600

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

Poskytovateľ

Poznámka: Zaregistrujte sa zadarmo alebo sa prihláste, aby ste získali všetky informácie.

Registrované od: 2023

Odoslať žiadosť

Telefón & Fax

+49 4181 ... inzercie

Tieto inzeráty by vás mohli tiež zaujímať.

Malý inzerát

Rimini

Rimini

749 km

Vertikálny tvar bloku

VIROmod. TNG-4

VIROmod. TNG-4

Malý inzerát

Deitingen

Deitingen

914 km

Nástroj brúske

W. ScherrerSB 10

W. ScherrerSB 10

Malý inzerát

Mindelheim

Mindelheim

683 km

Dvojitá pokosová pásová píla

MIOTALS 255 DG

MIOTALS 255 DG

Malý inzerát

Berlin

Berlin

610 km

Pick-up van

PEUGEOTBoxer Euro 5 3,80m

PEUGEOTBoxer Euro 5 3,80m

Malý inzerát

Zuzenhausen

Zuzenhausen

797 km

Shredder

ZERMAZRS

ZERMAZRS

Malý inzerát

Velbert

Velbert

950 km

Páskovací stroj

CyklopXZE-311

CyklopXZE-311

Malý inzerát

Sinsheim

Sinsheim

790 km

Rezací stroj

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

Malý inzerát

Zuzenhausen

Zuzenhausen

797 km

Bočné mlyny

ZERMAGSL 300

ZERMAGSL 300

Malý inzerát

Petrovče

Petrovče

432 km

Skartovač

Robust¸Reuser SD 700/22 kW

Robust¸Reuser SD 700/22 kW

Malý inzerát

Berlin

Berlin

617 km

Rotačný filter

SEITZ ENZINGER NOLLVACUBLOC

SEITZ ENZINGER NOLLVACUBLOC

Váš inzerát bol úspešne odstránený

Došlo k chybe