Použitá kompletná plniaca linka na tiché víno - 8000 fliaš za hodinu (BPH)APE Impianti

Použitá kompletná plniaca linka na tiché víno - 8000 fliaš za hodinu (BPH)

APE Impianti

Stav

Použitý

Umiestnenie

Taliansko

Zobraziť obrázky

Zobraziť mapu

Údaje o stroji

Cena a lokalita

- Umiestnenie:

- , Taliansko

Volať

Podrobnosti ponuky

- ID záznamu:

- A21193520

- Referenčné č.:

- LC597

- Naposledy aktualizované:

- dňa 09.02.2026

Popis

Technical Specifications & Performance Data

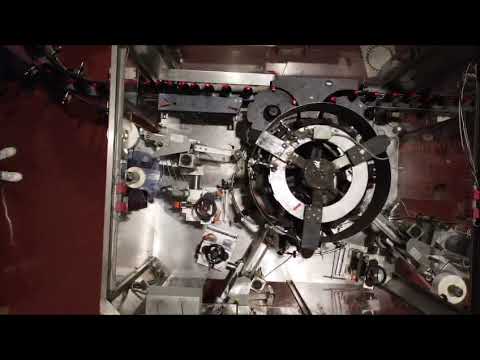

This used bottling line is engineered for reliable beverage production and downstream industrial packaging at rates of up to 8,000 bottles per hour. The configuration combines APE Impianti carton handling systems with KOSME labelling technology, delivering robust performance for second-hand applications and flexible format management, as commonly required with glass and PET bottles.

Production Speed: 8,000 bottles per hour

Compatible Formats: Standard carton pack pattern includes 12 x 0.75 L; additional formats manageable with change parts

Containers: Designed for bottle handling; configuration suitable for PET and glass (cylindrical containers)

Dkedpfx Adsyh E Hujreh

Labelling Systems: KOSME STAR 720 12T (cold glue), KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Packaging Modules: APE FORMA 2000 (carton erector), APE INCA 2010 (carton packer), APE INSER 2001 (divider inserter)

Electrical (Labellers): 400 V, 50 Hz; installed power 4 kW (STAR 720 12T) and 8 kW (EXTRA ADHESIVE 12T S3 E3)

Weights (Labellers): 2,650 kg (STAR 720 12T), 2,000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-marked components

Advanced Automation & Control Systems

The line utilizes modular automation across labelling and carton handling stations to ensure steady throughput. Operator-friendly controls on each module facilitate rapid commissioning and format changeovers. KOSME labelling machines feature standard European electrical specifications (400 V, 50 Hz) and matched installed power, guaranteeing precise label application at line speed. APE Impianti packaging modules offer synchronized motion sequences and interlocked safety guards for downstream processes.

Integrated start/stop logic and line accumulation to stabilize product flow

Rapid mechanical adjustments for format changes with guided setup steps

Interlocked safety fencing and emergency stops on the main machines

Clear HMI/operator interfaces per machine for format selection and diagnostics

Production Line Integration Capabilities

This production line is designed for inline operation with conveyors and buffering to achieve the 8,000 bph target. The dual labelling architecture—cold glue and self-adhesive—accommodates a wide range of label materials and presentation standards. Carton erecting, divider insertion, and packaging are fully integrated for efficient end-of-line handling, ensuring consistent carton quality for logistics and storage.

Inline configuration compatible with upstream/downstream machinery

Cold glue and self-adhesive labelling flexibility for front/back and wrap-around applications

Carton erecting, divider insertion, and packaging for 12 x 0.75 L packs

Suitable for multiple bottle sizes with appropriate change parts

Machine Condition & Maintenance History

This is a used filling and packaging solution with components from the years of construction...

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

This used bottling line is engineered for reliable beverage production and downstream industrial packaging at rates of up to 8,000 bottles per hour. The configuration combines APE Impianti carton handling systems with KOSME labelling technology, delivering robust performance for second-hand applications and flexible format management, as commonly required with glass and PET bottles.

Production Speed: 8,000 bottles per hour

Compatible Formats: Standard carton pack pattern includes 12 x 0.75 L; additional formats manageable with change parts

Containers: Designed for bottle handling; configuration suitable for PET and glass (cylindrical containers)

Dkedpfx Adsyh E Hujreh

Labelling Systems: KOSME STAR 720 12T (cold glue), KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Packaging Modules: APE FORMA 2000 (carton erector), APE INCA 2010 (carton packer), APE INSER 2001 (divider inserter)

Electrical (Labellers): 400 V, 50 Hz; installed power 4 kW (STAR 720 12T) and 8 kW (EXTRA ADHESIVE 12T S3 E3)

Weights (Labellers): 2,650 kg (STAR 720 12T), 2,000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-marked components

Advanced Automation & Control Systems

The line utilizes modular automation across labelling and carton handling stations to ensure steady throughput. Operator-friendly controls on each module facilitate rapid commissioning and format changeovers. KOSME labelling machines feature standard European electrical specifications (400 V, 50 Hz) and matched installed power, guaranteeing precise label application at line speed. APE Impianti packaging modules offer synchronized motion sequences and interlocked safety guards for downstream processes.

Integrated start/stop logic and line accumulation to stabilize product flow

Rapid mechanical adjustments for format changes with guided setup steps

Interlocked safety fencing and emergency stops on the main machines

Clear HMI/operator interfaces per machine for format selection and diagnostics

Production Line Integration Capabilities

This production line is designed for inline operation with conveyors and buffering to achieve the 8,000 bph target. The dual labelling architecture—cold glue and self-adhesive—accommodates a wide range of label materials and presentation standards. Carton erecting, divider insertion, and packaging are fully integrated for efficient end-of-line handling, ensuring consistent carton quality for logistics and storage.

Inline configuration compatible with upstream/downstream machinery

Cold glue and self-adhesive labelling flexibility for front/back and wrap-around applications

Carton erecting, divider insertion, and packaging for 12 x 0.75 L packs

Suitable for multiple bottle sizes with appropriate change parts

Machine Condition & Maintenance History

This is a used filling and packaging solution with components from the years of construction...

Inzercia bola automaticky preložená a vyskytli sa nejaké chyby prekladu.

Dokumenty

Poskytovateľ

Poznámka: Zaregistrujte sa zadarmo alebo sa prihláste, aby ste získali všetky informácie.

Registrované od: 2021

Odoslať žiadosť

Telefón & Fax

+39 344 0... inzercie

Tieto inzeráty by vás mohli tiež zaujímať.

Malý inzerát

Fumane (Verona)

Fumane (Verona)

752 km

Balenie kufrov

APE ImpiantiInca 2001

APE ImpiantiInca 2001

Malý inzerát

Fumane (Verona)

Fumane (Verona)

752 km

Prípad Erector

APE ImpiantiForm 1200 HM

APE ImpiantiForm 1200 HM

Malý inzerát

Fumane (Verona)

Fumane (Verona)

752 km

Balenie kufrov

APE ImpiantiINCA 2000

APE ImpiantiINCA 2000

Malý inzerát

Fumane (Verona)

Fumane (Verona)

752 km

Prípad Erector

APE ImpiantiForm 2000 HM SX

APE ImpiantiForm 2000 HM SX

Malý inzerát

Fumane (Verona)

Fumane (Verona)

752 km

Prípad Erector

APE ImpiantiFORM1500 HMB

APE ImpiantiFORM1500 HMB

Váš inzerát bol úspešne odstránený

Došlo k chybe